Timber frame is recognised as a standard method of building with an increasing amount of new homes built using this method.

Timber frame construction using standardised dimensional timber has become the dominant construction method in North America, Canada and Australia due to the economy of the method; use of sustainable material allows builders to build a structure quickly and efficiently while achieving a wide variety of architectural styles.

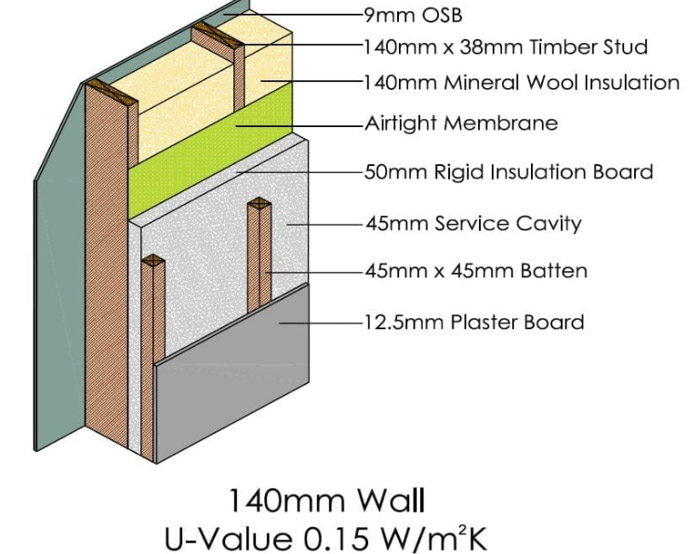

The structure of the timber frame walls are strengthened using OSB board to form a rigid panel which forms the support the roof structure.

Insulation

OX Timber frame panel insulation build up can be tailored to the client’s specification.

Our typical wall build up will meet insulation requirements if your build falls under part L regulations (new builds and some extensions) with a U-Value of 0.15 W/m2k.

Insulation for Defective block scheme

Cost savings on insulation in the OX timber frame can be attained part L

Vapour Control Layer

OX Timber Frame uses a technologically advanced vapour control membrane, which prevents moisture from entering the timber frame structure and has humidity controlling and insulating properties. The membrane makes the building wind-tight and waterproof.

What is a Vapour Control Layer & how do they work?

A Vapour Control Layer, or VCL for short, is a plastic layer that restricts the movement of warm, moist air from inside a property into the fabric of the building.

VCLs prevent excess moisture entering a wall’s cavity, behind the insulation. This reduces the risk of harmful interstitial condensation by ensuring that any moisture within the cavity is at a manageable level.

Benefits of a VCL

- Prevents interstitial condensation which reduces the chance of mould and rot

- Protects the insulation in a concrete floor build up from wet screeds

- Reduces heat loss and improves energy efficiency

Weep vents are installed in the outer cavity wall to allow airflow within the cavity removing any excess moisture.

External Cladding

Most common external cladding options are:

- Masonry block with render.

- Brick or stone.

- Metal cladding such as zinc, copper, corten steel etc.

- Wood fibre or cement board with a render system.

- Durable timber cladding such as cedar or larch.

Timber Quality

OX Timber Frame’s solid timber is vacuum treated to give complete protection against decay and insect attack allowing for longevity and durability of the timber frame structure, equal to a masonry house.

The structure of the timber frame walls are strengthened using OSB board to form a rigid panel which forms the support the roof structure.

OX timber products are certified and comply with Irish national design standards and building regulations.

Fire Performance

OX Timber frames are designed to provide the required level of fire resistance and acoustic performance.

Fire resistance is achieved through specified fire protective wall linings such as 15mm gypsum plasterboard, a cavity barrier system and fire stop as outlined in the Irish Standard.

Advantages of Timber Frame

- Highly structural, sustainable and efficient.

- Lifetime savings due to energy efficient structure.

- Speed of installation allows for a quicker overall build time.

- Reduction of waste on-site.

- Greater control and flexibility to the construction process.

- Considerably less impact to the environment.

Building Regulations

Part L – Conservation of Fuel & Energy of Building Regulations.

Part L of the regulations aim to limit the usage of fossil fuels and Carbon Dioxide (CO2) emissions from the operation of buildings.